Sigma Motion Actuators

Engineering, Development & Technology

Sigma's motion approach is heavily aligned to the science of motion. We call this Motion Integrity™ and it’s about accuracy in both position, velocity, acceleration and jerk. Motion Integrity™ is achieved through our Velocity Trap™ algorithm which is calculated in real-time in the controller, per actuator. This is the core fundamental of our motion system, the base layer.

On top of the base layer, are two key fundamentals, scaling and motion cueing. The goal is to optimize motion cueing so the motion system has the ability to scale each motion layer to 100% of reality. We believe 100% scaling is vital to an authentic motion system.

Our approach to motion cueing is unique for each of our 9 motion layers. There is no one approach that fits all. We spend most of our R&D time developing many types of motion cueing algorithms.

Our haptic feedback layers, also have unique motion cueing so that the vibrations do not interfere with the motion integrity of the other motion layers related to pitch, roll and heave.

Motion Layers Defined

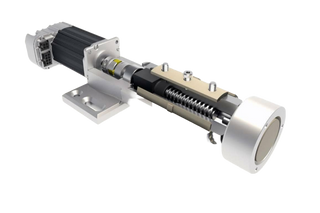

Sigma develops and builds professional plug and play motion systems for various professional consumers and industrial applications. Our systems are completely designed, engineered and manufactured in California, USA. Our in-house manufacturing approach allows us to fully optimize our products and processes and make continual iterative product updates.